In industrial production, materials usually don’t cause problems on day one. Most issues show up months later. Seals start leaking. Parts harden. Elasticity disappears. Equipment that used to run fine suddenly needs frequent maintenance. After dealing with enough of these cases, you start to realize one thing: material choice decides how much trouble you’ll have later.

This is where silicone comes in. Silicone isn’t perfect, and it’s not cheap compared to many rubbers. But in real industrial environments, it’s one of the few materials that stays predictable. Heat, cold, vibration, chemicals, it doesn’t panic easily. That stability is the main reason silicone keeps showing up in machinery, electronics, automotive systems, renewable energy equipment, and even food and pharmaceutical production lines.

Below is a rough overview of the silicone products we most commonly see in industrial projects, what they’re used for, and why engineers keep choosing them.

| Silicone Product Type | Typical Applications | Key Functions |

| O-Rings / G-Rings / U-Rings | Hydraulic systems, pneumatic systems, pumps and valves | Sealing, leak prevention, high-temperature resistance |

| Cushions / Vibration Dampers | Precision instruments, machinery | Shock absorption, vibration reduction, equipment protection |

| Conductive / Insulating Parts | PCB protection, electronic components, sensors | Electrical insulation, conductivity, protection |

| Silicone Hoses / Tubing | Liquid or gas transport, food and medical industries | Transport, heat resistance, flexibility |

| Protective Caps / Covers | Industrial equipment, dust/water/chemical protection | Protection, dustproof, waterproof, corrosion resistance |

| Customized Industrial Parts | Tailored for specific industrial designs | High precision, special performance requirements |

From simple sealing rings to custom-shaped structural parts, industrial silicone covers a wide range. Instead of listing everything like a manual, I’ll focus on what actually matters in daily use: why silicone works, where it performs best, and what people usually overlook.

Why Silicone Works So Well in Industry

Temperature Resistance

Most people start paying attention to silicone because of temperature. And honestly, that’s fair.

Silicone stays elastic roughly from -60℃ to 230℃. In practice, that means it survives places where normal rubber slowly gives up. Cold rooms, outdoor equipment, engine compartments, heated pipelines, silicone handles these without dramatic changes.

What matters more is not the maximum temperature on paper, but how the material behaves after long exposure. In many projects, silicone seals still feel flexible after years near heat sources. That’s something you notice only after replacing failed parts again and again.

Chemical Stability

In hydraulic systems, cleaning processes, or fluid transfer, materials are constantly exposed to oils, detergents, or mild chemicals. Some rubbers swell quietly. Others crack.

Silicone is relatively boring in this sense. It doesn’t react much. That’s good.

Less swelling means fewer sealing failures. Less degradation means longer replacement cycles. In food and pharmaceutical systems, this stability is especially important because material breakdown is not acceptable.

Electrical Insulation

In electronics, silicone usually works in the background. Insulating sleeves, protective pads, sealing gaskets around sensors, nobody notices them unless something fails.

Silicone’s dielectric performance stays stable even when temperature changes. That’s why it’s often chosen for PCB protection and sensor sealing. It’s not exciting, but it prevents a lot of silent problems.

Elasticity and Sealing

From an installer’s point of view, silicone is forgiving.

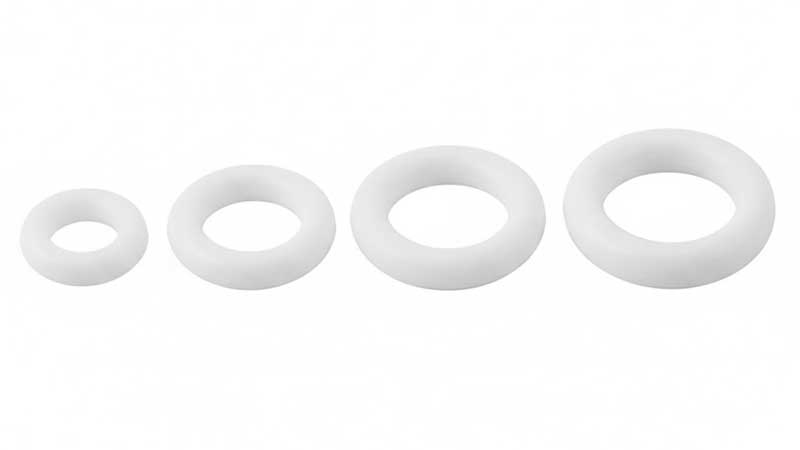

It compresses evenly, recovers well, and tolerates slight misalignment. That’s why O-rings, U-rings, and custom seals made from silicone are widely used.

For vibration control, silicone pads and dampers also do a solid job. In precision equipment, vibration is often underestimated. A well-chosen silicone damper can noticeably reduce noise, wear, and measurement drift.

Common Industrial Silicone Products in Real Use

Sealing Rings: O-Rings, G-Rings, U-Rings

These are everywhere. Pumps, valves, compressors, hydraulic cylinders.

In real selection work, temperature range is only one part. Hardness, compression set, and dimensional tolerance usually decide success or failure. Silicone performs reliably across a wide temperature range, but the formulation still needs to match pressure and movement conditions.

Cushioning and Vibration Dampers

Silicone cushioning parts protect equipment in two ways: they absorb shock and reduce continuous vibration.

We often adjust hardness and thickness based on load and vibration frequency. There’s no universal solution here. But silicone gives enough flexibility in design to fine-tune performance instead of accepting compromise.

Conductive and Insulating Silicone Parts

This is where silicone becomes more than a rubber.

Conductive silicone is used in battery packs, sensors, and contact interfaces. Insulating silicone protects cables and high-voltage components. The same base material, different formulations, completely different functions.

Selection here usually depends on environment first, then electrical performance.

Silicone Hoses and Tubing

Silicone hoses are common in food, pharmaceutical, and laboratory systems. Flexibility, transparency, and cleanliness are the main reasons.

High-temperature hoses handle heat above 150℃ without stiffening. Medical-grade hoses reduce contamination risk. Wall thickness and diameter are often customized to match flow and installation constraints.

Protective Caps and Covers

Protective silicone parts don’t look important, but they save time and money. Dust caps, waterproof covers, temporary protection during transport or assembly, all simple, all useful.

Silicone lasts longer than many plastics in these roles, especially when heat or chemicals are involved.

Custom Industrial Silicone Parts

Once designs become complex, standard parts stop working.

Custom silicone parts are used for battery sealing, engine gaskets, electronic housings, and structural interfaces. Compression molding or injection molding is chosen based on geometry and tolerance requirements.

This is where material experience matters most. A small change in formulation or mold design can completely change performance.

Silicone Molding Processes for Industrial Products

Product performance depends on both material and molding process. Common industrial processes include:

- Injection Molding: High-precision parts like small seals or electronic pads. Supports complex shapes with high consistency.

- Compression Molding: Suitable for high-volume seals or thick-wall components. Simple, stable, and efficient.

- Extrusion: Continuous production of hoses, strips, and sealing profiles. Length and cross-section can be customized.

These processes ensure precision and allow flexible adaptation to industrial requirements.

Surface Treatment and Printing on Silicone

Surface treatments like coating, plating, or anti-stick processes improve wear resistance and adhesion. Printing methods such as screen or pad printing add logos, scales, or markings using high-temperature, chemical-resistant inks. This ensures clear identification in industrial environments, aiding installation and maintenance.

Quality Control and Testing of Industrial Silicone

High-performance silicone requires strict quality control:

Raw Material Testing: Tensile strength, temperature resistance, chemical stability, and other properties ensure compliance with industrial standards.

Finished Product Testing: Dimensional accuracy, sealing performance, and aging resistance guarantee safe and reliable use.

Certifications and Standards: Depending on application, silicone may require ASTM, ISO, RoHS, or even FDA certification for food and medical industries.

Conclusion

Silicone doesn’t solve every problem, but in industrial environments, it solves many of the expensive ones.

When chosen correctly, it reduces maintenance, extends service life, and makes systems more predictable. That’s why it continues to replace less stable materials as equipment becomes more demanding.

We deal with complex geometries, tight tolerances, and performance-critical applications every day. Our team works with compression molding, injection molding, and extrusion, supported by modern equipment and practical quality control. If you’re looking for a silicone supplier who understands real production challenges, we’re always open to discussing your project.