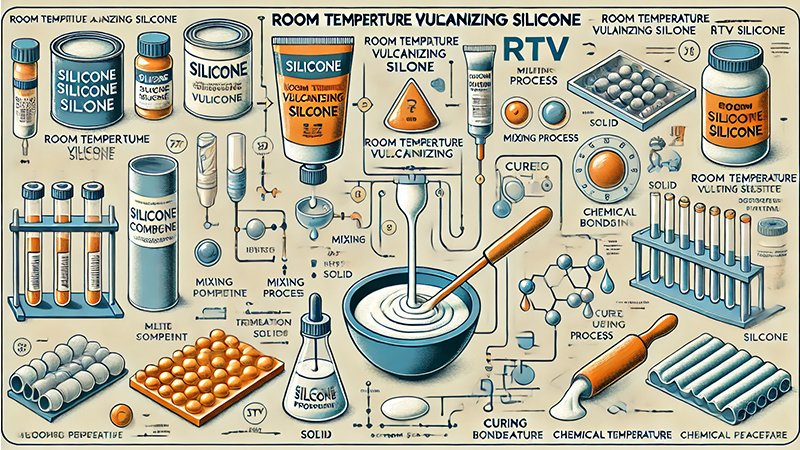

Room temperature vulcanizing (RTV) silicone is a versatile material widely used in various industries. Known for its ease of use and excellent performance, RTV silicone is ideal for applications requiring durable and flexible bonds.

RTV silicone is a type of silicone that cures at room temperature, eliminating the need for heat. This curing process is initiated by moisture in the air or through a chemical reaction between two components. RTV silicone offers excellent adhesion, flexibility, and resistance to extreme temperatures, making it suitable for sealants, adhesives, and molds. Its ability to cure without heat makes it a convenient and efficient solution for many applications.

Knowing the advantages and applications of RTV silicone can help you make informed decisions. Let’s explore its properties, uses, and benefits in detail.

How Does Room Temperature Vulcanizing Silicone Work?

RTV silicone cures at room temperature through a chemical reaction. There are two main types of RTV silicone: one-component (1K) and two-component (2K) systems.

One-Component RTV Silicone

- Moisture Curing: One-component RTV silicone cures upon exposure to moisture in the air. This makes it convenient for applications where heating is impractical.

- Easy Application: It comes ready to use, making it ideal for quick repairs and sealing jobs.

Two-Component RTV Silicone

- Chemical Reaction: Two-component RTV silicone requires mixing two parts, typically a base and a curing agent. The mixture then cures at room temperature.

- Controlled Curing: This type allows for more control over the curing process and is suitable for larger or more complex applications.

What Are the Benefits of Using RTV Silicone?

RTV silicone offers numerous advantages over other types of adhesives and sealants. These benefits make it a preferred choice in various industries.

- Ease of Use: Cures at room temperature without the need for heat or special equipment.

- Versatility: Suitable for a wide range of applications, including sealing, bonding, and molding.

- Durability: Resistant to extreme temperatures, chemicals, and UV light, ensuring long-lasting performance.

- Flexibility: Maintains flexibility even after curing, which is crucial for applications involving movement or vibration.

What Are the Applications of RTV Silicone?

RTV silicone is used in a wide range of applications due to its versatile properties. These applications span across various industries, highlighting its adaptability and reliability.

Automotive Industry

- Gaskets and Seals: RTV silicone is used for making gaskets and seals that need to withstand high temperatures and harsh environments.

- Bonding and Sealing: Ideal for bonding and sealing components in automotive assembly.

Construction and Building

- Sealants: Used for sealing joints and gaps in buildings, providing excellent weather resistance.

- Adhesives: Suitable for bonding materials like glass, metal, and plastic in construction projects.

Electronics

- Encapsulation: RTV silicone is used for encapsulating electronic components to protect them from moisture and contaminants.

- Insulation: Provides insulation for electronic parts due to its dielectric properties.

Consumer Goods

- Mold Making: Ideal for creating molds for casting resins, wax, and other materials.

- Kitchenware: Used in the manufacture of bakeware and kitchen utensils due to its non-toxic nature.

How to Apply RTV Silicone Correctly?

Proper application of RTV silicone is crucial for achieving optimal results. Following best practices can ensure strong bonds and effective seals.

Steps for Application

- Surface Preparation: Clean and dry the surfaces to be bonded or sealed. Remove any dirt, grease, or contaminants.

- Applying the Silicone: For one-component RTV, apply directly from the tube or cartridge. For two-component RTV, mix the components as per the manufacturer’s instructions.

- Smoothing the Silicone: Use a spatula or finger to smooth the silicone before it starts to cure. For a clean finish, use soapy water to prevent sticking.

- Curing Time: Allow the silicone to cure fully. One-component RTV typically cures in 24 hours, while two-component RTV may vary based on the formulation.

What Are the Common Challenges with RTV Silicone?

While RTV silicone offers many benefits, it also presents certain challenges. Understanding these challenges can help you mitigate issues and ensure successful applications.

- Curing Time: Curing time can vary based on temperature and humidity, potentially slowing down the process.

- Adhesion Issues: Proper surface preparation is essential to prevent adhesion problems.

- Storage and Handling: RTV silicone must be stored correctly to maintain its effectiveness. Exposure to moisture can prematurely initiate curing.

How Does RTV Silicone Compare to Other Materials?

RTV silicone offers distinct advantages over other materials such as acrylics, polyurethanes, and epoxies. Comparing these materials can help you choose the best option for your specific needs.

Comparison with Acrylics

- Flexibility: RTV silicone maintains flexibility better than acrylics, which can become brittle over time.

- Durability: RTV silicone is more resistant to UV light and extreme temperatures.

Comparison with Polyurethanes

- Chemical Resistance: RTV silicone offers better resistance to chemicals compared to polyurethanes.

- Temperature Tolerance: RTV silicone can withstand higher temperatures without degrading.

Comparison with Epoxies

- Ease of Use: RTV silicone is easier to apply and cures at room temperature, while epoxies often require precise mixing and higher curing temperatures.

- Elasticity: RTV silicone remains flexible after curing, whereas epoxies can be more rigid.

Future Trends in RTV Silicone?

As technology advances, new formulations and applications for RTV silicone continue to emerge. These innovations aim to enhance its performance and expand its use in various fields.

Emerging Trends

- Eco-Friendly Formulations: Development of RTV silicone products with reduced environmental impact, using sustainable ingredients and processes.

- Enhanced Properties: Innovations in formulations to improve adhesion, curing time, and resistance to extreme conditions.

- Advanced Applications: Increased use in high-tech industries such as aerospace, renewable energy, and advanced manufacturing.

Conclusion

Room temperature vulcanizing silicone is a versatile and reliable material with numerous applications across various industries. Its ease of use, durability, and flexibility make it an excellent choice for sealants, adhesives, and molds. Despite some challenges, proper application techniques and adherence to best practices ensure successful results. As technology evolves, new trends in RTV silicone will continue to enhance its capabilities and broaden its applications.

Related Articles:

Difference between Curing and Vulcanization

Silicone Vulcanization: A Comprehensive Analysis from Fluid to Elasticity