Surface treatment determines not only the look but also the lifetime of silicone products. Choosing the wrong process can lead to premature wear or peeling.

Selecting the right surface treatment — sandblasting, etching, coating, or plasma — ensures both texture appeal and long-term durability.

When I worked on developing a new baby spoon handle, the team spent weeks comparing different surface finishes. Some looked beautiful but failed after a few dishwasher cycles. That experience made me realize how crucial the right surface treatment choice is for silicone products.

Surface Treatment Process Spectrum?

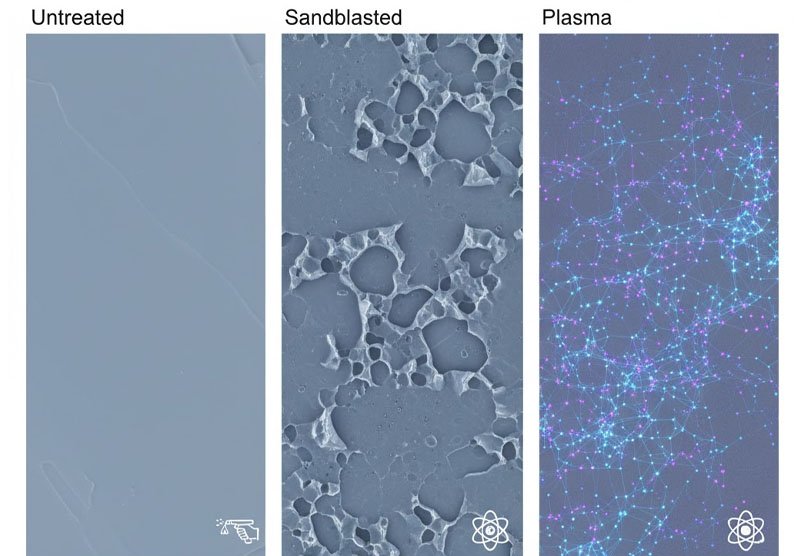

Each surface treatment has a distinct effect on appearance, tactile feel, and performance. Understanding their differences helps us choose the most suitable one for the application.

Sandblasting, etching, coating, and plasma treatment each modify the silicone surface differently, influencing texture, adhesion, and resistance.

Silicone is chemically inert and smooth, which makes it difficult for coatings or inks to adhere. To enhance adhesion and create desired textures, surface modification is essential.

Common Silicone Surface Treatments

| Process | Mechanism | Typical Purpose | Durability |

|---|---|---|---|

| Sandblasting | Physical abrasion | Matte texture, grip enhancement | High |

| Etching | Chemical micro-roughening | Precise micro-patterns | Medium |

| Coating | Applied protective or decorative layer | Color or gloss effect | Variable |

| Plasma | Molecular activation | Adhesion improvement | Medium-high |

Each process can be combined — for example, plasma pre-treatment before coating improves bonding strength. For food-grade silicone, only FDA-approved chemicals and coatings are acceptable.

Abrasion and Chemical Resistance Performance Evaluation?

Surface treatments must withstand both mechanical and chemical stress during use and cleaning. Testing ensures durability under real-world conditions.

Abrasion, solvent wipe, and cross-hatch adhesion tests evaluate how long a treated surface will maintain its performance.

I once received a batch of coated baby bowls that started fading after just a week of use. After testing, we found that the coating failed the 50-cycle abrasion test — it peeled at just 30 cycles. That data pushed us to adjust the coating formula and add plasma pre-treatment, which raised performance to over 100 cycles.

Typical Durability Tests

| Test | Method | Evaluation Criteria |

|---|---|---|

| Cross-hatch adhesion | ASTM D3359 | 5B = excellent adhesion |

| Abrasion resistance | Taber or rubbing test | No visible wear after 100 cycles |

| Solvent wipe | 50 wipes with IPA | No color transfer or peeling |

Will Coating Layers Peel Off in High-Temperature Dishwashers?

Yes, if not properly cured or if adhesion is poor. Coatings should be validated for heat and moisture resistance — especially for baby and kitchen silicone products exposed to repeated dishwashing.

Texture Design and Tactile Feel?

Surface design defines not just visual style but also how users experience the product. Texture consistency matters for both aesthetics and function.

Texture and tactile feel depend on surface treatment type, pattern depth, and silicone hardness.

When designing a pacifier handle, we tested three surface finishes: matte sandblasted, etched fine-line, and soft-touch coated. Users preferred the sandblasted finish because it felt dry yet grippy — ideal for baby handling.

Texture Classification and Tactile Effect

| Texture Type | Creation Method | Tactile Feel | Application |

|---|---|---|---|

| Matte | Sandblasting | Dry, anti-slip | Handles, grips |

| Micro-pattern | Laser etching | Precise tactile design | Buttons, logos |

| Coated gloss | Clear coating | Smooth, reflective | Premium look |

| Plasma-modified | Plasma treatment | Enhanced adhesion without texture change | Pre-treatment layer |

Texture uniformity depends on consistent mold surface finish. During mass production, any variation in mold roughness or treatment time can cause visual mismatch between batches.

Food Contact and Migration Risks?

Not all surface treatments are safe for food-contact silicone. Improper coatings or etching residues may pose migration risks.

For food-grade silicone, treatments must comply with FDA and LFGB regulations to ensure no harmful migration or chemical release.

In one baby feeder project, we initially used a soft-touch coating that looked great but failed migration testing due to residual solvents. Switching to plasma treatment with natural texturing solved the problem while maintaining the same tactile quality.

Safety Considerations

| Treatment | Food-Grade Compatible | Key Precautions |

|---|---|---|

| Sandblasting | Yes | Use clean media (no silica contamination) |

| Etching | Limited | Must fully remove chemical residues |

| Coating | Conditional | Use FDA/LFGB-certified coating only |

| Plasma | Yes | No chemical residue, ideal for bonding |

Regulatory testing, such as total migration or specific migration tests, should be part of validation before mass production. For baby products, any applied coating should have verified resistance to saliva and repeated boiling cycles.

Mass Production Consistency and Cost?

Durability and aesthetics mean little if results can’t be repeated at scale. Consistent surface treatment ensures predictable performance batch after batch.

Surface treatment consistency depends on process control, media quality, operator training, and equipment stability.

I learned during one large-volume kitchenware project that even slight changes in sandblasting pressure or media size affected the gloss level. Standardizing every parameter — from nozzle distance to treatment time — was the key to repeatable finishes.

Process Control Table Example

| Factor | Control Method | Target |

|---|---|---|

| Sandblasting pressure | Digital gauge | 0.4 MPa ± 0.05 |

| Etching time | Timer-controlled | 90 sec ± 5 sec |

| Coating thickness | Wet film gauge | 15–20 μm |

| Plasma power | PLC-controlled | 300 W ± 5% |

Cost Considerations

- Sandblasting: Low equipment cost, medium labor intensity.

- Etching: Moderate cost, requires chemical disposal management.

- Coating: Higher cost, limited by curing and durability.

- Plasma: Higher setup cost, but clean and automated.

Process stability directly impacts scrap rate and overall cost efficiency. For long-term reliability, automation and inline monitoring are worth the investment.

Conclusion

Surface treatment defines both the look and life of silicone products. Balancing aesthetics, durability, safety, and cost requires a clear understanding of each method’s strengths and limits.

Need help selecting the best surface treatment?

Submit your durability goals and testing methods to our team, and we’ll recommend the optimal treatment combination for your silicone product at RuiYang Silicone.