In the world of silicone products, the curing method plays a key role. Choosing between platinum-cured and peroxide-cured silicone has a direct impact on performance, appearance, safety, and product lifespan.

So what’s the difference between these two curing methods? And how do you choose the right one?

This article will walk you through everything, from how they work to how they perform, where they’re used, and how to make the best choice for your needs.

What’s the Difference Between Platinum Curing and Peroxide Curing?

Silicone needs to go through curing to become solid and usable. There are two main curing methods: platinum curing and peroxide curing. Each follows a different chemical path and leads to different results. Understanding how they work helps us choose the right silicone for each purpose.

Platinum Cure

| Feature | Platinum Cured (Addition Cure) |

| Curing Mechanism | Addition reaction: Silicon-hydride (Si-H) groups react with vinyl (Si-Vi) groups in the presence of a platinum catalyst to form stable Si-C bonds. |

| Byproducts | None or minimal (only a trace of hydrogen gas, which evaporates). The process is very clean. |

| Catalyst Sensitivity | High. Can be easily inhibited by sulfur, amines, or organotin compounds. These can cause incomplete curing. |

| Curing Speed | Controllable. Strongly affected by temperature. |

| Analogy | Like “precise molecular puzzle pieces” locking into place — with no leftovers. |

Pro Tip: The purity of the platinum catalyst matters a lot. Even tiny impurities can interfere with the reaction, making the product unusable.

Peroxide Cure

| Feature | Peroxide Cured (Free Radical Cure) |

| Curing Mechanism | Free radical reaction: Organic peroxides break down at high temperatures to create free radicals. These radicals attack the silicone chains, creating active points that link together. |

| Byproducts | Yes. Small organic acids (like benzoic acid) are common. These need to be removed in a second curing step. |

| Catalyst Sensitivity | Low. Less affected by impurities in the environment. |

| Curing Speed | Generally fast, but requires higher temperatures. |

| Analogy | Like “a fast-moving dance of molecules” — powerful, but leaves a bit of a mess to clean up. |

Pro Tip: Post-curing is a must. It removes byproducts, improves purity, and enhances physical properties like compression set, especially important for long-term use.

How Do These Two Curing Methods Affect Silicone’s Performance?

Understanding the curing process is important, but the real question is: how do they compare in everyday use? Here’s a side-by-side look at key performance differences.

| Performance Factor | Platinum-Cured Silicone | Peroxide-Cured Silicone |

| Purity | Very high. No leaching or odor. | Lower. Can contain small molecules unless post-cured. |

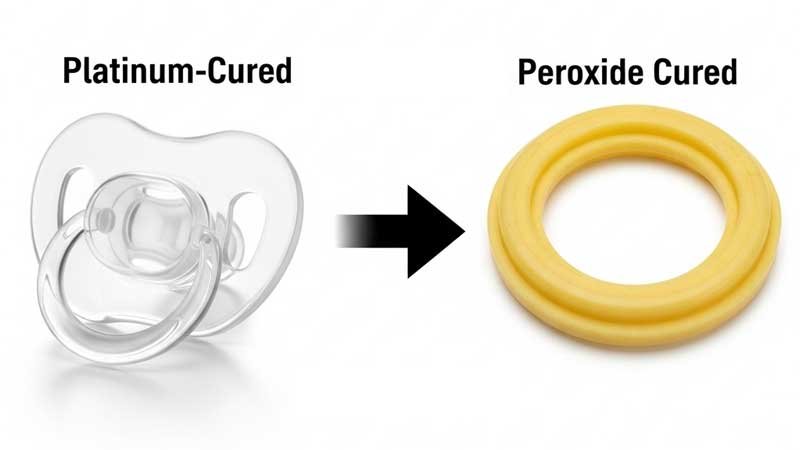

| Transparency | Excellent. Can be crystal clear. | Fair. Usually translucent or milky white. |

| Biocompatibility | Outstanding. Suitable for medical and food use. | Good. Can meet food-grade standards after proper post-cure, but not for implants. |

| Physical Strength | Superior tensile and tear strength. Good rebound. | Good. Meets most industrial needs. |

| Compression Set | Very low. Keeps shape under pressure. Great for seals. | Acceptable. Works well for general sealing. |

| Color Stability | Excellent. Resists yellowing. | More likely to discolor with heat or UV. |

| Temperature Resistance | Wider range. Performs well in high heat. | Good, but less stable over time. |

| Aging Resistance | Great resistance to UV, ozone, and gamma rays. | Decent, but performance may drop after repeated sterilization. |

| Shrinkage | Very low. Holds shape well — ideal for precision parts. | Slightly higher, which can affect tight tolerances. |

| Cost | Higher, due to catalyst and cleanroom needs. | Lower. More economical for mass production. |

Where Are Platinum-Cured and Peroxide-Cured Silicone Used?

Different curing methods give silicone very different properties. Their unique strengths help them shine in different industries, from medical and food to automotive and electronics.

Platinum-Cured Silicone: Trusted for Safety and High Performance

Medical Devices and Implants

Platinum-cured silicone is extremely pure and biocompatible. It’s soft, clean, and safe for long-term contact with the human body.

- Ventilator tubing needs to stay flexible and safe during extended use.

- Pacemaker insulation must be durable, non-reactive, and extremely pure.

- Infusion pump tubing can’t release any substances that could mix with medication.

- Endoscope seals must resist steam sterilization and stay chemically stable.

Food Contact Products

When safety and cleanliness matter most, platinum-cured silicone is the top choice.

- Baby bottle nipples and pacifiers need to be tasteless, odorless, and toxin-free.

- Premium baking molds and kitchenware must handle high heat and be easy to clean.

- Food-grade gaskets and seals in coffee machines or water filters help keep drinks safe.

Electronics and Precision Devices

Platinum-cured silicone offers excellent transparency and stability.

- LED lenses and potting materials need to stay clear and resist yellowing.

- Sensor protection requires a clean, stable material that won’t release corrosive substances.

- Aerospace electronics rely on silicone that performs under extreme conditions.

Optics and Consumer Goods

This silicone is also perfect for high-end products that touch the skin or need a sleek look.

- Diving mask seals must be clear, flexible, and watertight.

- Silicone heads on beauty tools should be skin-friendly and resist oils and makeup.

Peroxide-Cured Silicone: A Reliable and Cost-Effective Choice

General Industrial Sealing

Peroxide-cured silicone works well for many everyday applications. It’s strong, flexible, and affordable.

- Gaskets for machines need to handle pressure and temperature changes.

- O-rings are used in pumps, valves, and hydraulic systems.

- Flexible industrial hoses and ducts move liquids or air in demanding environments.

Automotive Parts

It’s tough enough for many car parts and offers good heat and chemical resistance.

- Cylinder head gaskets must hold their shape near hot engines.

- Cable insulation protects wires from wear and weather.

- Flexible exhaust connectors absorb vibration and heat.

Building Materials

Peroxide-cured silicone is also used in construction for sealing and weather protection.

- Window and door seals keep out water, dust, and noise.

- Structural sealants help fill gaps and hold glass in place.

Everyday Electronics

This type of silicone is found in many consumer devices.

- Remote control buttons need to be soft, durable, and responsive.

- Rice cooker or pressure cooker seals must resist steam and last through daily use.

Consumer Products

For cost-effective, everyday items, peroxide-cured silicone is a practical choice.

- Silicone handles on kitchen tools offer grip and insulation.

- Fitness tracker bands are soft, sweat-resistant, and long-lasting.

How Do You Choose Between Platinum-Cured and Peroxide-Cured Silicone?

When it comes to production and product development, choosing the right curing system is key. Based on my experience, here are some simple tips to help you choose.

High Purity Needed

- If the product will directly contact the human body like medical implants or baby items, platinum-cured silicone is the only safe choice. There’s no room for compromise when it comes to safety.

Appearance and Clarity

- If your product needs to look crystal clear or keep its color over time, go with platinum-cured. It offers superior transparency and long-term color stability.

Demanding Physical Properties

- For products that need excellent rebound, minimal compression set, or high strength, especially complex or precise parts, platinum-cured silicone performs better.

Budget Matters

- If you’re working with limited funds, and the product doesn’t need extreme purity, peroxide-cured silicone may be a better fit. Any by-products can usually be removed through proper post-curing, keeping things safe and cost-effective.

Processing Simplicity

- When you want a smoother production process that doesn’t require a high-cleanliness environment, peroxide-cured silicone is easier to handle. It allows more flexible processing times and stable output.

Conclusion

Both curing types have their place. Platinum-cured silicone is the cleanest and most precise, perfect for medical, food-grade, and high-performance products. Peroxide-cured silicone is more budget-friendly, reliable for many industrial uses, and well-suited for mass production, especially when followed by a proper post-cure.

If you’re looking to create a silicone product and aren’t sure which type of silicone suits your needs, we can help. Let’s work together to develop a custom solution that balances safety, function, and cost.