I’ll be direct: most silicone overmolding failures aren’t caused by “bad adhesion.”

They come from teams assuming silicone behaves like a melt-processable plastic once it’s in the mold.

It doesn’t. And the gap shows up late—usually after tooling money is already spent.

What follows isn’t a catalog of options. It’s how these bonds actually behave on the floor, over time, and under repetition.

Silicone Bonding Is Not One Problem

When people say “silicone doesn’t stick,” they’re compressing three different mechanisms into one complaint:

- Chemical compatibility

- Surface energy and cleanliness

- Mechanical constraint during cure

Miss any one of these, and the bond may look fine on day one—and peel on day thirty.

That’s why early prototypes often pass hand-pull tests and then fail in the field.

Silicone + PC (Polycarbonate)

What Works — and Why It’s Fragile

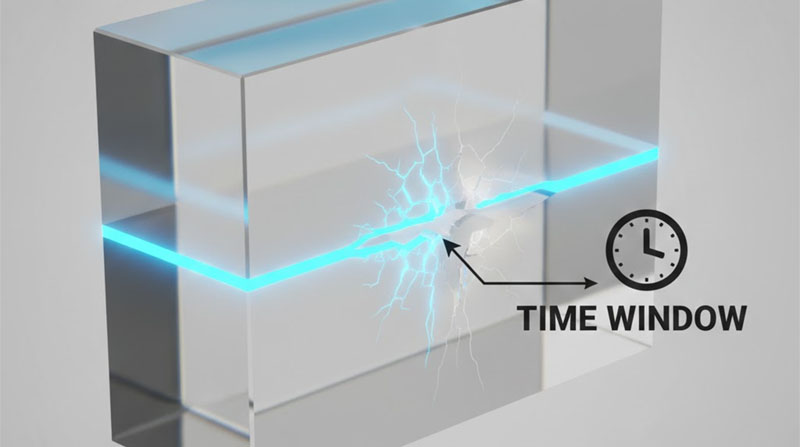

Silicone can bond to PC, but only within a narrow processing window.

- PC has moderate surface energy

- It tolerates plasma or corona activation

- Certain addition-cure silicones will chemically anchor if the surface is activated correctly

In production, this bond is process-sensitive, not material-sensitive.

What actually causes drift:

- Mold temperature creeping upward

- Activation aging (PC parts sitting too long after plasma)

- Release agent vapor migrating from nearby tools

Once the surface re-oxidizes, adhesion drops fast—and not linearly.

Why teams underestimate this:

PC is “easy” in plastic terms, so engineers expect stable behavior. Silicone punishes that assumption.

Silicone + PA (Nylon)

Strong on Paper, Unstable in Reality

PA looks promising because:

- Higher polarity than PC

- Better initial wetting

- Often stronger lab pull results

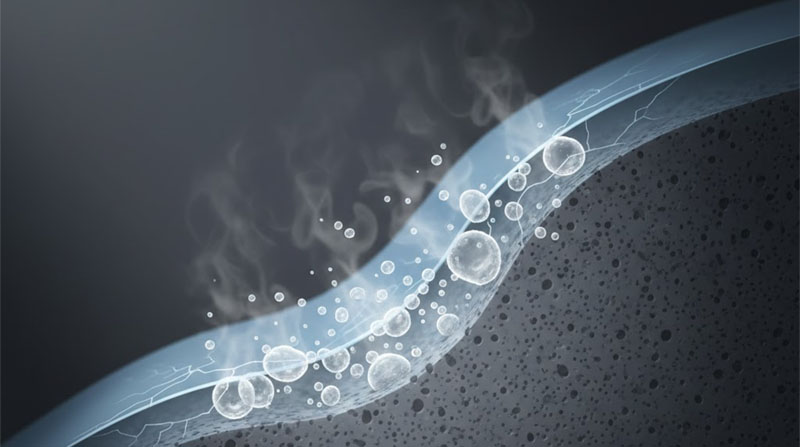

But PA introduces a variable silicone hates: moisture.

Even “dry” nylon reabsorbs water from ambient air. That moisture:

- Interferes with interfacial bonding

- Causes micro-voiding during cure

- Changes bond strength batch to batch

Glass-filled PA makes it worse. You get:

- Inconsistent surface exposure

- Fiber print-through

- Local stress risers at the bond line

The trap:

Early samples molded straight after drying perform well. Production parts that wait 24–72 hours don’t.

Silicone + Metal (Steel / Aluminum / Stainless)

The Most Reliable—If You Respect the Prep

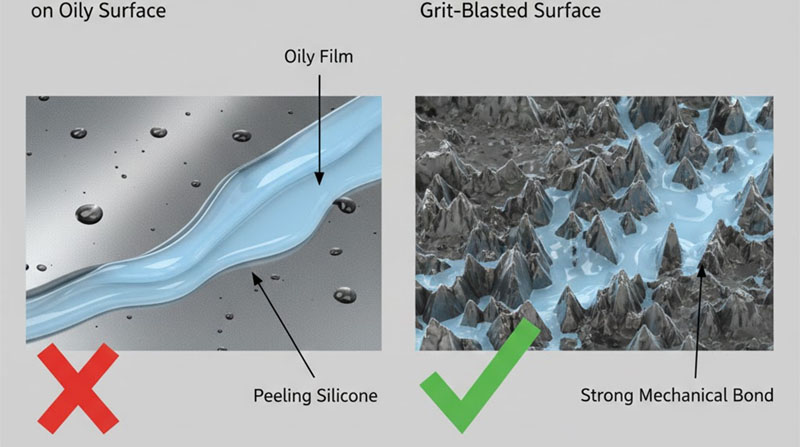

Metal is where silicone bonding is most predictable, if surface prep is treated as a process, not a step.

Stable bonds usually require:

- Grit blasting or chemical etching

- Controlled oxide layer

- Primer matched to silicone chemistry

Once locked, these bonds survive:

- Thermal cycling

- Long-term compression

- Repeated mechanical load

But shortcuts fail quietly.

Common issues we see:

- “Light” blasting to save time

- Finger oils after cleaning

- Primer thickness variation across cavities

Unlike PC or PA, metal doesn’t forgive inconsistency—but it also doesn’t drift over time if controlled.

Mechanical Locking Is Not a Backup Plan

Design teams often say:

“If adhesion fails, the geometry will hold it.”

That’s optimistic.

Mechanical retention works with chemical bonding, not instead of it.

Without adhesion:

- Silicone cold-flows under compression

- Edges lift first

- Micro-movement grows with every cycle

Over months, not weeks.

Good overmold designs assume both:

- Chemical bond for sealing

- Mechanical features for load sharing

Bad ones assume geometry alone solves chemistry.

Tooling Reality: Where Bonds Actually Fail

From a manufacturing perspective, bonding issues usually surface at:

- Cavity-to-cavity variation

- Second-shift changeovers

- Insert handling outside the mold

Not during first-article approval.

Silicone cure hides problems.

You don’t see delamination until:

- Environmental aging

- Assembly stress

- Repeated compression

By then, the argument is already happening.

Feasibility Is a Control Question, Not a Material Question

Can silicone be overmolded onto PC, PA, or metal?

Yes. All three.

But feasibility depends on whether the program can control:

- Surface state

- Time between prep and molding

- Cure profile consistency

- Insert handling discipline

Most feasibility studies ignore these because they’re not in the CAD model.

That’s where the misjudgment starts.

Where Teams Usually Decide Too Late

The biggest mistake isn’t picking the wrong bonding method.

It’s locking tooling before validating bonding under production-like timing.

If bonding only works when:

- Inserts are molded immediately

- Operators are careful

- Conditions are “ideal”

Then it doesn’t work.

Silicone doesn’t fail loudly.

It waits.

And when it goes, it peels—slowly, quietly, and expensively.